Au Boulot à Vélo 2025: A New Record for MBTM!

Learn more

Teamentwicklungstag – A Day Dedicated to Team Cohesion

Learn moreNews

Au Boulot à Vélo 2025: A New Record for MBTM!

Au Boulot à Vélo 2025: A New Record for MBTM!

From June 1st to 30th, 2025, Mercedes-Benz Trucks Molsheim took part in the "Au Boulot à Vélo" challenge, an inter-company challenge that encourages employees to cycle to work. A great opportunity to promote sustainable mobility, physical activity, and team spirit!

This year, 53 employees took up the challenge, achieving impressive results:

- 9,266.6 km cycled

- 1,720 bonus km earned by finding all 50 checkpoints of the challenge

- 926.6 bonus km gained through participation in the photo contest

That’s a total of 11,913.48 km in just one month! It’s 2,161.4 km more than in 2024!

Beyond the athletic performance, this initiative also had a strong positive environmental impact. The total distance cycled represents approximately 2.59 tons of CO₂ emissions avoided, using the average emissions of a thermal vehicle as a reference.

A huge thank you to all participants for their energy, enthusiasm, and commitment.

See you in 2026 — ready to break another record!

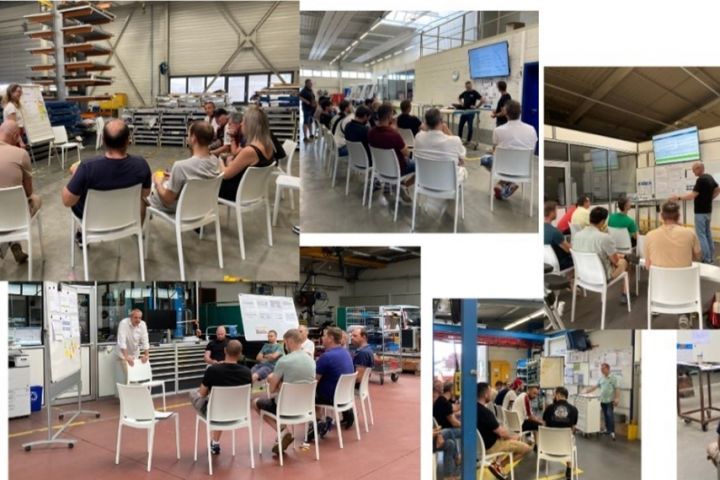

Teamentwicklungstag – A Day Dedicated to Team Cohesion

Teamentwicklungstag – A Day Dedicated to Team Cohesion

On Thursday, June 26, 2025, we organized our Teamentwicklungstag, a day dedicated to team cohesion and employee recognition.

This initiative reflects our commitment to building a work environment where everyone understands their role in collective success and where collaboration between teams is actively encouraged.

The morning began with a pleasant breakfast gathering, followed by several discussion sessions:

- A collective reflection on individual contributions to the company’s results, focusing on each person’s role in overall performance and incentive mechanisms.

- Targeted discussions on concrete daily challenges, chosen by the teams themselves: communication, inter-service cooperation, shared vision, process improvement, or team cohesion.

These exchanges allowed everyone to express themselves, share ideas, and lay the groundwork for future improvement actions.

Under the sun, over 500 employees gathered for a barbecue. Grilled dishes, salads, desserts, and drinks marked this enjoyable break.

The second part of the day was devoted to an interdepartmental discovery activity. Production departments had the opportunity to visit neighboring sectors in order to:

-

Rediscover the roles and missions of other departments

-

Better understand internal interactions

-

Foster cross-departmental dialogue

This day strengthened the bonds between teams and confirmed the importance of collaboration and exchange in building together a work environment that is ever more efficient and fulfilling.

MBTM achieves another milestone with the ISO 50001 certification

At Daimler Truck, sustainability is at the heart of our strategy. Mercedes-Benz Trucks Molsheim is fully in line with this dynamic by obtaining ISO 50001 certification.

This standard is dedicated to energy efficiency. It aims to optimize the site’s energy consumption while maintaining equivalent vehicle production. It complements our previous certifications, namely ISO 9001 (quality management system), ISO 14001 (environmental management system) and ISO 45001 (occupational health and safety management system). These certifications reflect our ongoing commitment to quality, environmental management and workplace safety.

Concrete Actions to Improve Our Energy Performance

For several years now, MBTM has been implementing concrete measures to limit its environmental impact. One of the most significant initiatives is the installation of 13,000m² of photovoltaic panels on the roofs of our two parking lots, which generate approximately 20% of the site's electricity consumption.

A Long-Term Vision

This certification supports the objectives of Daimler Truck's ‘Green Production’ initiative, which aims for a gradual reduction of CO₂ emissions, improved energy efficiency, increased use of renewable energies, and a reduction of waste across the group's industrial sites.

Worldwide, Daimler Truck recorded a 13.8% decrease in CO₂ emissions linked to production in 2024 compared to the previous year, and a 35.3% reduction compared to 2021. These results are the outcome of coordinated actions, among which the actions at Molsheim contribute.

Acting Today for Tomorrow

This new certification represents a significant and encouraging step in our commitment to more responsible energy management. However, there are still areas for improvement in order to fully achieve our long-term goals.

Recognizing that the energy transition is a long-term process, we are pursuing our efforts with determination, capitalising on what works and improving where we can.

Testimonials

Felix, IT Hub - Smart Factory

Felix is responsible for developing and maintaining a technological platform that enables the collection, processing, and provision of production data.

Jordan, Data Engineer

Jordan is tasked with developing and maintaining systems that gather, store, and process large-scale data, ensuring it is readily available to meet business requirements.

Alexander, Data Scientist

Alexander uses statistics, machine learning algorithms, and his expertise to predict various future trends, such as production quality changes, penne frequency rates, and product recommendations.

The history of the Molsheim factory

Located in Molsheim, Alsace, this facility stands as the French hub of Mercedes-Benz Trucks. With its 600 employees, it is the largest truck conversion site and also serves as the headquarters of the Mercedes-Benz Custom Tailored Trucks (CTT) division, which coordinates and fulfills customers' special requests worldwide. The factory was established in 1967. Since 1991, it has been performing conversions on behalf on the Wörth plant.